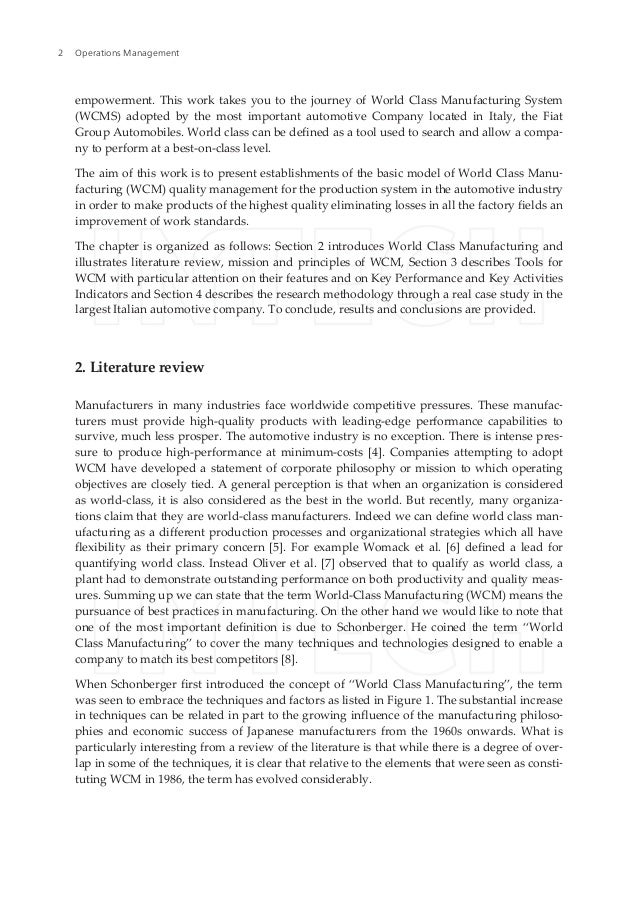

Thus, from literature survey it is inferred that it is not possible to use the specific single tool to achieve worldclass performance and address all the manufacturing components It is inferred that to address all the components of the manufacturing system the following tools are necessary (see Table 12)Offshore manufacturing will remain attractive for a wider range of products as long as there are differences in manufacturing cultures as well In the AT&T study an important motive for moving offshore was that it provided an opportunity to restructure operations immediately that were not operating at worldclass standards onshoreKeyWords World Class Manufacturing, Workplace Organization, Cost Deployment, Lean management 1 Introduction The present work is focused on the World Class Manufacturing, an innovation program based on Continuous Improvement, that provides the elimination of all types of waste and loss of production through the

Chrysler S World Class Manufacturing Academy In Warren Mi Automototv Youtube

World class manufacturing factory

World class manufacturing factory-Beyond WorldClass The New Manufacturing Strategy the mechanics of JIT and TQM—rather than on their substance, the skills and capabilities that enable a factory to excel Being worldThe term World Class Manufacturing is used to describe the highest level of manufacturing performance Some of the concepts of World Class Manufacturing go all the way back to Henry Ford's River Rouge plant in 1914 Achieving World Class Manufacturing comes only when the improvement effort is integrated across all functions in the company

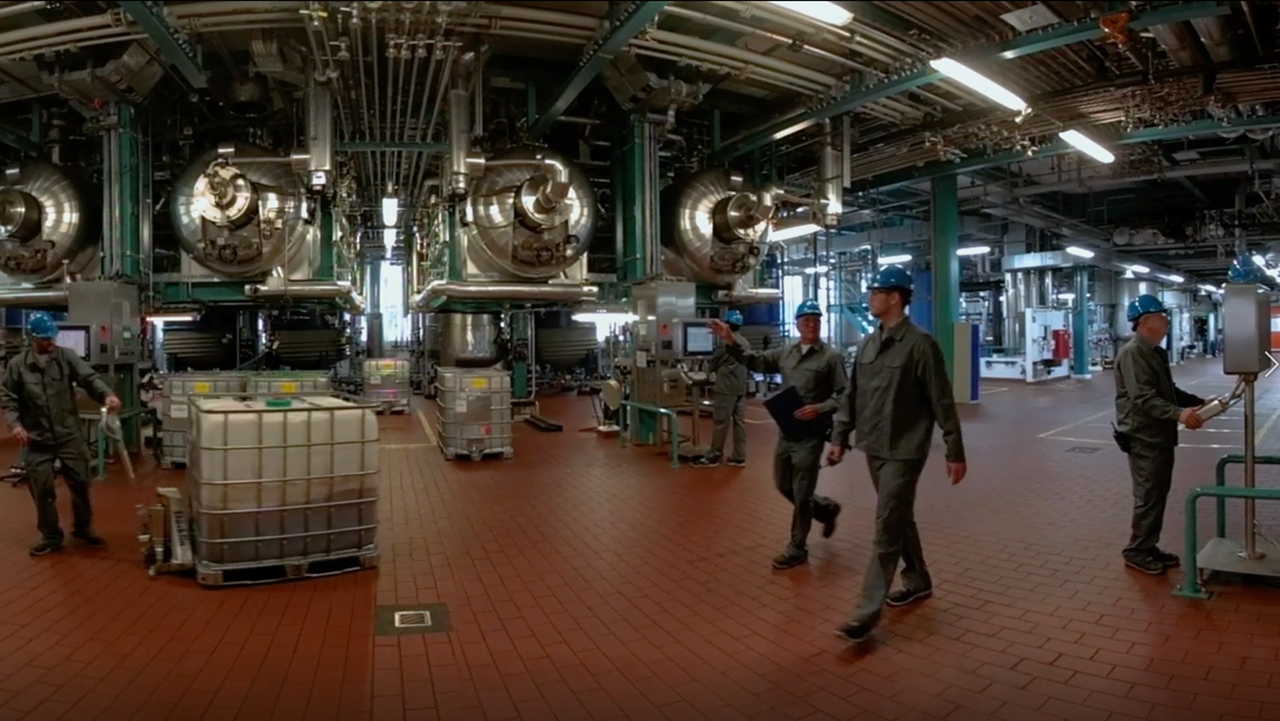

Gionee S World Class Manufacturing Facility Is One Of The Best In The World Http Gionee Co In Manufacturing Facility Manufacturing Facility World

For some time to come, China will be "the world factory" with its low production costs, huge labor pool, vast talent base, and business ecosystem Article Sources Investopedia requires writersWorld class manufacturing The goal of Pacefactory is to identify any changes in process that allow you to maintain a pace that minimizes waste This pace should also be balanced to address ergonomic and safety concernsSix root causes of poor labour productivity;

The benchmark for WorldClass is 85% OEE (100% OEE means no losses at all) Very few factories in the world are operating at these efficiency levels, hence is why it's regarded as WorldClass To achieve 85%, your availability, throughput, and yield losses would need to total 15% or less of your total available timeIn fact, World Class Manufacturing is a manufacturing system defined by 6 International companies including Fiat Group Automobiles with the intent to raise their performances and standards to World Class level with the cooperation of leading European and Japanese experts and this includes all the plant processes including quality, maintenanceManufacturing cycle time Cycle time is the total time from the beginning to end of a process In manufacturing, it measures the time taken for a product to pass through all machines, processes and cycles to become a finished product The total time an item spends in the manufacturing system between the order release and completion is the

In 05, we were the first company in our industry to publicly disclose our factory base, in the interests of transparency and collaboration Nike's Manufacturing Map is a tool to learn about the independent factories contracted to make Nike and Converse products – including the names and location of each factory, the types of product made, the factories that supply our collegiate productManufacturing Cost Deployment is a decisionsupport method proposed by Yamashina and Kubo 1 Today, it is one of the pillars of the World Class Manufacturing program 68 Its greatest advantage is that it helps assign costs to the root causes of losses in the manufacturing process and sorts the losses according to potential for improvementThis is part of the series of blog posts we are writing called "Measuring for Excellence", in which we'll be exploring the strategies and best practices some of the most successful companies employ to build a culture of manufacturing excellence in their organization

Skf Enters The World Of Manufacturing Using World Class Digital Technology

World Class Cleaning Clean Team

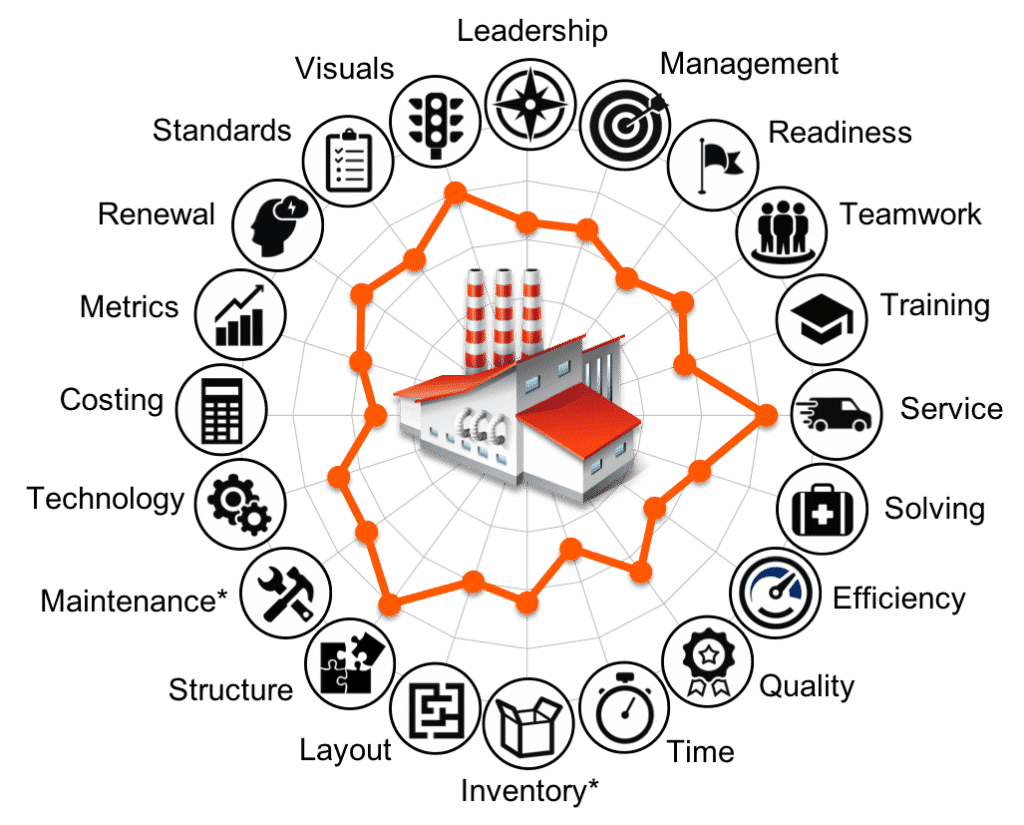

WCM Global quality through World Class Manufacturing " WCM aims to ensure that the FCA Group's facilities are flexible and competitive with the best in the world " Sergio Marchionne, CEO of Fiat Chrysler Automobiles NV Read more Giambattista Vico Plant The Panda factory wins WCM gold Visiting the plant and experiencing the passion of its peopleWORLD CLASS MANUFACTURING WorldClass Manufacturing principles apply to all aspects of plant organization,from the quality system to maintenance, from cost control to logistics, in aperspective of continuous improvement WorldClass Manufacturing (WCM) in fact was born of the collaborationbetween Fiat and the best European and Japanese expertsOffshore manufacturing will remain attractive for a wider range of products as long as there are differences in manufacturing cultures as well In the AT&T study an important motive for moving offshore was that it provided an opportunity to restructure operations immediately that were not operating at worldclass standards onshore

Gkn To Build New World Class Manufacturing Facility In Japan E Hike

World Class Manufacturing Elica

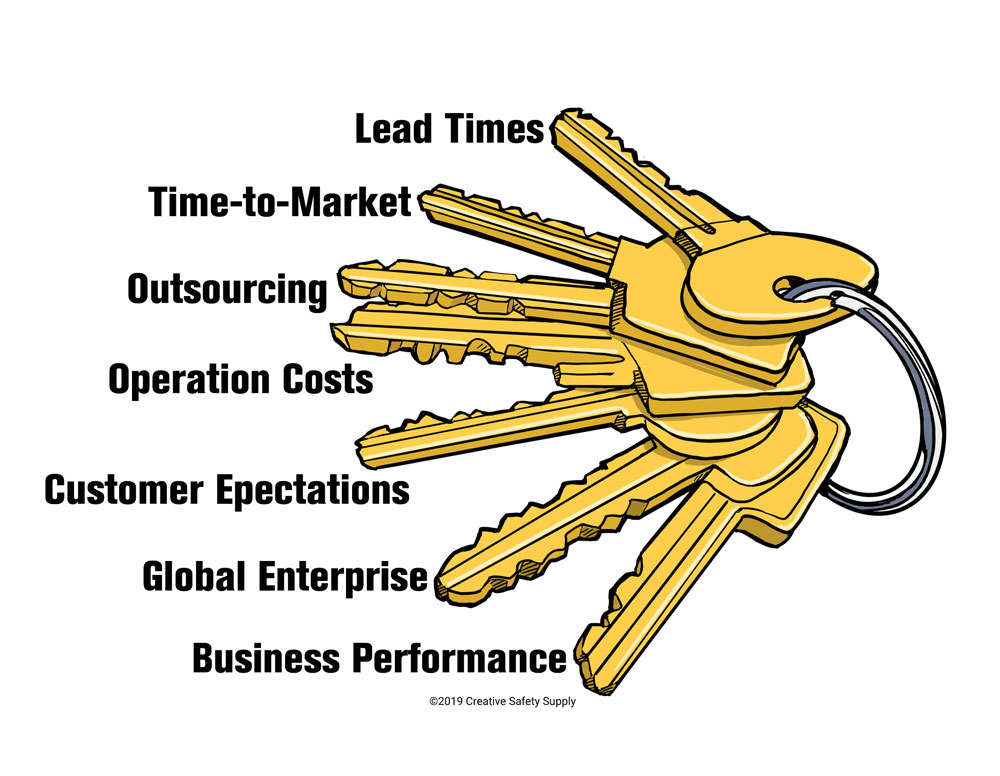

To be world class requires an overall willingness to establish closer connections with everyone from customers and suppliers to workers, an unwavering commitment to selfanalysis and improvement, and an aggressive approach to technologies that can help turn visionary strategies into goldmedal realitiesTypically, we can get a factory up and running within a week Contact us today to start managing your factory KPIs You might also find these posts useful 6 essential KPIs for worldclass factory performance;Key characteristics of the World Class Manufacturing concept The Cost Deployment pillar is of particular interest because it differs from the typical XPS (see this post to learn what is "typical") Cost Deployment is a sevenstep accounting technique for assigning actual costs to each loss and waste that happens in a factory

Jupiter Bach Has Initiated Construction Of A New World Class Manufacturing Site In China Jupiter Bach

World Class Manufacturing Archives Allis Roller Precision Machined Parts Welding And Services

World Class Manufacturing About SaintGobain India SaintGobain designs, manufactures and distributes materials and solutions which are key ingredients in the wellbeing of each of us and the future of allFPE Global unveils worldclass manufacturing factory Posted on 22 Sep 16 by Jonny Williamson Specialist engineering firm, FPE Global has opened the doors to its new advanced test facility and manufacturing operation, with the aim of strengthening its services to a growing international customer baseWorld Class Manufacturing (WCM) is a structured and integrated production system that involves all manufacturing processes in the site and entire organization from the leadership to the people on the shop floor WCM is usually represented as a temple with 10 technical and 10 managerial pillars that have to be managed properly in order to

Rolls Royce System Store Solutions Case Study

How To Build A World Class Manufacturing Facility Navigate Content

The following is a list of the world's largest manufacturing companies, ordered by revenue in millions of US dollars according to the Fortune Global 500 in the year Currently the 100 biggest companies by revenue are included *Revenue with asterisk(s) aren't found or confused according to Fortune Global 500 in the yearWCM has its foundations in the Total Productive Maintenance (TPM) a maintenance process developed in Japan for improving productivity by making processes more reliable & less wasteful What is World Class Manufacturing?Since 1978, World Upholstery and Trim has been Manufacturing and Distributing worldwide car/auto trim parts like seat covers/upholstery, carpets, convertible tops, headliners, door panels, sunvisors, complete soft interior trim and rubber seals/parts for classic European cars We make parts for cars like Alfa Romeo, Fiat, BMW, Ferrari, Jaguar, Mercedes, Porsche and Saab

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Iowa Dept Of Agriculture Land Stewardship Burlington Ia Is The Backhoe Capitol Of The World Secretary Mlnaig Toured Cnhindustrial This Afternoon A World Class Manufacturing Facility And World Class Iowa Jobs

MercedesBenz Factory Plant Tour World class operation/manufacturing plant tour that is free See 7 traveler reviews, 100 candid photos, and great deals for Sindelfingen, Germany, at TripadvisorFor example, suppose a factory has a centralized team for equipment maintenance, but separate workers for various processes The maintenance team will be involved everywhere They might be overwhelmed by an initial factorywide project, but do well in one area at a timeWorld class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industry

World Class Manufacturing Fca Group

Royal 4 Wise Wms Auto Parts Factory Royal 4 Systems

Five musthave features for your next shop floor data collection systemKeep Your Training Short The human brain acts as a limit to the amount of information we can process and store at any one time It's only a small amount of information–about four "bits" at any one time And we can only keep that information in our working memory (you might think of this as shortterm memory) for a very short period of timeWorld Class Manufacturing is a set of concepts, policies, techniques, and principles for operating and managing a manufacturing company The concept of World Class Manufacturing is based on the positive results achieved by Japanese manufacturing companies after World War II A common definition of World Class Manufacturing is when United States' companies began implementing Lean concepts in order to stay competitive in global markets

Whirlpool S Poprad Site Passes The First World Class Manufacturing Audit Whirlpool Corporation

World Class North American Manufacturing Facility Vintex Inc Custom Engineered Coated Textile Solutions

Best in class manufacturing how to create a factory of the future Manufacturing facilities have evolved significantly since the first Industrial Revolution With each Industrial Revolution, the complexity of manufacturing facilities continues to grow whilst at the same time, expectations continue to riseAs a result, multinationals now generally apply a mixture of logistic, quality and productivity oriented improvement methods, eg LeanSix SigmaTPM This combined approach is often called World Class Manufacturing of WCM, a term popular for already thirty years to describe several mixed continuous improvement approachesSome Perspective The WorldClass OEE figures are interesting and useful, but keep in mind that they have roots in a particular place (Japan), at a particular time (1970s), and in a particular industry (automotive) The reality is that most manufacturing companies, even today, have OEE scores closer to 60% We work with thousands of manufacturing companies, and we see more companies with OEE

World Class Manufacturing Youtube

World Class Manufacturing Facility

Beyond WorldClass The New Manufacturing Strategy the mechanics of JIT and TQM—rather than on their substance, the skills and capabilities that enable a factory to excel Being worldAn OEE score of 100% is perfect production manufacturing only good parts, as fast as possible, with no stop time An OEE score of 85% is considered world class for discrete manufacturers For many companies, it is a suitable longterm goalKey characteristics of the World Class Manufacturing concept The Cost Deployment pillar is of particular interest because it differs from the typical XPS (see this post to learn what is "typical") Cost Deployment is a sevenstep accounting technique for assigning actual costs to each loss and waste that happens in a factory

Great Lakes Industry Capabilities Manufacturing World Class Manufacturing At Great Lakes Industry Inc Manufacturing Visual Factory Great Lakes

Syngenta Group Opens World Class Manufacturing Plant In Switzerland Business Wire

World Class Manufacturing About SaintGobain India SaintGobain designs, manufactures and distributes materials and solutions which are key ingredients in the wellbeing of each of us and the future of allThe term World Class Manufacturing is used to describe the highest level of manufacturing performance Some of the concepts of World Class Manufacturing go all the way back to Henry Ford's River Rouge plant in 1914 Achieving World Class Manufacturing comes only when the improvement effort is integrated across all functions in the companyAbout Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators

Lodz Radomsko Wroclaw And Poprad Pass World Class Manufacturing Audits Whirlpool Corporation

Michigan Manufacturing Cleaning Company World Class Works Michigan Facility Maintenance

For some time to come, China will be "the world factory" with its low production costs, huge labor pool, vast talent base, and business ecosystem Article Sources Investopedia requires writersKeyWords World Class Manufacturing, Workplace Organization, Cost Deployment, Lean management 1 Introduction The present work is focused on the World Class Manufacturing, an innovation program based on Continuous Improvement, that provides the elimination of all types of waste and loss of production through theSyngenta Group today opens its first major manufacturing facility since the formation of the Group in June This step marks a major strategic inv Syngenta Group Opens WorldClass

India Case World Class Manufacturing Facility At Pithampur Mp Youtube

Reengineering The Factory A Primer For World Class Manufacturing Shores A Richard Amazon Com Books

WCM is a mindset based on a continuous improvement approach / 2World Class Solutions Global OEMs and Middle Market OEMs no longer need to choose between outsourcing to contract manufacturer or building vertical integration A Virtual Assembly Factory solution seamlessly integrates customer processes to provide a fully integrated and scalable manufacturing solutionToo many consulting companies see "lean" as a goal in itself I have never seen it that way but always think that the goal is something else Often it is about improving productivity, sometimes being able to postpone investments or improving product quality

About Us Giti Global

Conference On Apparel Manufacturing In Tirupur News Industrie

NIKE, Inc announced today a partnership with Flex (Nasdaq FLEX), a worldclass global manufacturer, to accelerate NIKE's vision to bring advanced innovation to its manufacturing supply chainWorld Class Manufacturing (WCM) vs Lean Manufacturing While lean manufacturing is a popular model to improve your business, world class manufacturing (WCM) offers several key advantages This broader look at your entire enterprise can help you gain a distinct advantage over your competitorsIn fact, World Class Manufacturing is a manufacturing system defined by 6 International companies including Fiat Group Automobiles with the intent to raise their performances and standards to World Class level with the cooperation of leading European and Japanese experts and this includes all the plant processes including quality, maintenance

3 Keys For World Class Manufacturing

Inside Our World Class Manufacturing Plant In Poprad Slovakia Youtube

Factory Vastu has seen an unprecedented increase in demand over the years With the advent of globalization and a rapidly growing economy, the need to set up industries has been more than ever And so has been the demand for industrial Vastu From large scale mega factories to small scale industries, the pace of industrialization has been phenomenal over the yearsWorld Class Plastics, Inc Since startup in 1994, World Class Plastics, Inc has endeavored to be a 'world class' provider of thermoplastic injection molded products and services The company has earned its position in the industry through superb customer service and technical supportWorld Class Plastics, Inc Since startup in 1994, World Class Plastics, Inc has endeavored to be a 'world class' provider of thermoplastic injection molded products and services The company has earned its position in the industry through superb customer service and technical support

World Class Manufacturing Magna International Office Photo Glassdoor Ca

How It Works At A World Class Manufacturing Plant Of Assa Abloy Youtube

The term World Class Manufacturing is used to describe the highest level of manufacturing performance Some of the concepts of World Class Manufacturing go all the way back to Henry Ford's River Rouge plant in 1914 Achieving World Class Manufacturing comes only when the improvement effort is integrated across all functions in the company

Chrysler S World Class Manufacturing Academy In Warren Mi Automototv Youtube

Emt International Processing Equipment For Digital Printing Paper And Converting Industries

Tofas 17 Sustainability Report

Fca Us World Class Manufacturing Academy Spreads Its Roots To Indiana Conceptcarz Com

Chrysler S World Class Manufacturing Training Saving Millions In Cost Wardsauto

Bystronic Presents World Class Manufacturing News Eng

Iveco Defence Vehicles And New Holland Agriculture Facilities Earn Bronze Status In World Class Manufacturing Wcm Program Europawire Eu The European Union S Press Release Distribution Newswire Service

World Class Manufacturing Facility

Syngenta Group Opens World Class Manufacturing Plant In Switzerland Business Wire

Wcm Timeline Fca Group

Amazon Com Learning From World Class Manufacturers Szwejczewski M Jones Malcolm Books

Unilevergulf Su Twitter Japanese Scientist Dr Hajime Yamashina Professor Emeritus At Kyoto University Created The Concept Of World Class Manufacturing The Premier Industry Benchmark For Manufacturing Here Are His Top Protocols That

Euroblech 18 World Class Manufacturing Bystronic

World Class Manufacturing Mem673 Youtube

Medbio Expands Manufacturing Capacity With Second World Class Facility Medbio Inc Medical Biotechnology Manufacturing

Factory Cartoon Png Download 1292 601 Free Transparent World Class Manufacturing Png Download Cleanpng Kisspng

Fpe Global Unveils World Class Manufacturing Factory The Manufacturer

World Class Manufacturing

Planning For Factory Automation A Management Guide To World Class Manufacturing Vanderspek Peter G Amazon Com Books

World Class Hose Manufacturing Plant In Tuas Singapore

Manufacturer Of Dry Type Medium Voltage Transformers

Taiwanglass 台玻集團

World Class Manufacturing Information And Free Guides

Lvd Implements World Class Manufacturing Initiative Lvd Group

Wcm World Class Manufacturing November Mission Finantare Ro

Global Quality Through World Class Manufacturing Fca Group

World Class Manufacturing Information And Free Guides

World Class Manufacturing Facility

Fca Us Detroit Engine Plant Celebrates Silver Award In World Class Manufacturing Conceptcarz Com

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations

World Class Manufacturing

Fca Us World Class Manufacturing Academy Spreads Its Roots To Indiana Conceptcarz Com

World Class Manufacturing

Iveco Madrid Plant Becomes First To Achieve Gold Level Designation In World Class Manufacturing

Fpt Industrial Sete Lagoas Engine Plant Achieves Silver Level Designation In World Class Manufacturing

Odm Oem Manufacturing Choose An Industry Leader Provider Paragon Water Systems

Welcome To View View Smart Windows

Cnh Industrial Newsroom The New Holland Jesi Plant In Italy Achieves Silver Level Designation In World Class Manufacturing

How To Build A World Class Manufacturing Facility Navigate Content

Fca Us Jefferson North Assembly Plant Earns World Class Manufacturing Bronze Award Conceptcarz Com

Manufacturing And Engineering Industries Bulgaria Bg Advise

World Class Manufacturing Wcm Armacell

Fpe Global Unveils World Class Manufacturing Factory The Manufacturer

Have You Seen Gionee Industrial Park One Of The Largest Mobile Manufacturing Facilities Of The World Manufacturing Manufacturing Facility Industrial Park

Dek A Chinese Local With Uk Origins Solar Novus Today

World Class Manufacturing Takes Center Stage At Chrysler Plants Wardsauto

Gionee S World Class Manufacturing Facility Is One Of The Best In The World Http Gionee Co In Manufacturing Facility Manufacturing Facility World

How To Build A World Class Manufacturing Facility Navigate Content In Manufacturing Facility Chemical Industry

Building Up The World Class Smart Manufacturing Factory Through Digital Transformation Youtube

.jpg)

The Iveco Plant In Sete Lagoas Brazil Achieves Silver Level Designation In World Class Manufacturing Lectura Press

Nupress First Class Engineering

10 Steps To Achieve World Class Manufacturing Maintenance Practices

Whirlpool Corporation Highlights World Class Manufacturing Production System And Employees Globally On Manufacturing Day Whirlpool Corporation

How To Build A World Class Manufacturing Facility Navigate Content

Nik J Miles The Fca Mack Avenue Penstar Engine Plant In Detroit Is Celebrating They Were Honored With A Silver Award In The Company S World Class Manufacturing Wcm Methodology T Co U6fcjk9gs7

Morse Manufacturing Opens World Class Manufacturing Facilities Mheda

How Augmented Reality Can Support World Class Manufacturing Inglobe Technologies

Lvd Implements World Class Manufacturing Initiative Lvd Group

Lean Audit Operations Diagnostics Book Leanmap

Iveco Madrid Site Earns Gold Status In The World Class Manufacturing Program Becomes Cnh Industrial S Highest Ranking Facility Europawire Eu The European Union S Press Release Distribution Newswire Service

Automation And Lean Supply Chain At Fiat Chrysler Planet Lean

Improve Your World Class Manufacturing Rating Ifm Electronic

World Class Manufacturing Ltd Basildon To Sell Basildon Unit Echo

Westfall Technik Acquires Ama Plastics

Friday Fact Operational Excellence For World Class Manufacturing Faber Infinite

Advanced Metal Components Plant Tour Swainsboro Coastal Chapter

World Class Manufacturing Saic Hongyan Official Website

Bharat Forge Leading Tool And Die Manufacturer

World Class Manufacturing Makigami Info

World Class Manufacturing Fusion Group Limited

World Class Manufacturing Saic Hongyan Official Website

Good Start Implementation Of The World Class Manufacturing Project Centravis

No comments:

Post a Comment